The development and production of ultraviolet (UV) coated medical devices are complex processes that require precision, accuracy, and adherence to strict regulatory standards. As the demand for advanced medical devices continues to grow, manufacturers seek reliable and efficient solutions to streamline the UV light curing coating process and maintain the highest level of quality. Uvitron’s power supplies play an essential role in facilitating the UV light curing of medical devices, ensuring consistent and robust performance throughout the entire process.

Medical devices that require UV light curing include catheters, stents, and implantable devices such as pacemakers and artificial joints. UV light curing is a process that involves the use of ultraviolet light to cure a thin layer of coating material onto the surface of the medical device. This coating provides a protective layer that can reduce the risk of infection, prevent corrosion, and improve the biocompatibility of the device.

The Crucial Role of Power Supplies in the Medical Device Coating Process

Consistent and Precise Energy Delivery

A stable and reliable power supply is crucial for maintaining the integrity and performance of the medical device coating process. Uvitron’s power supplies provide consistent energy delivery, ensuring that UV light curing systems can achieve the desired thickness and uniformity of the applied coatings. This level of precision is essential for meeting the stringent requirements of the medical industry, where variations in coating thickness can significantly impact device performance and safety.

Optimized Efficiency for Reduced Downtime

Efficient power supplies minimize energy waste and reduce the overall cost of production. Uvitron’s power supplies are designed to optimize energy usage, ensuring that UV light curing equipment operates at peak efficiency. By reducing downtime and lowering energy consumption, Uvitron’s power supplies help manufacturers maintain a lean and cost-effective production process.

Ensuring Safe and Reliable UV Light Curing

Medical device coatings must meet stringent regulatory standards to ensure safety, efficacy and biocompatibility. These standards encompass a variety of criteria, including electrical safety and performance specifications. Uvitron’s power supplies are engineered to reliably maintain these material safety properties throughout the curing process.

Scalability and Adaptability

As medical device manufacturers continue to innovate and explore new UV light curing technologies, power supplies must be capable of adapting to evolving needs. Uvitron’s power supplies offer scalability and flexibility, allowing manufacturers to integrate them into UV light curing systems with varying power requirements and configurations. This adaptability ensures that power supplies can accommodate emerging technologies and advancements in the medical device coating industry.

Advantages of Uvitron’s UV Arc Lamp Power Supplies for Medical Device Coating Process

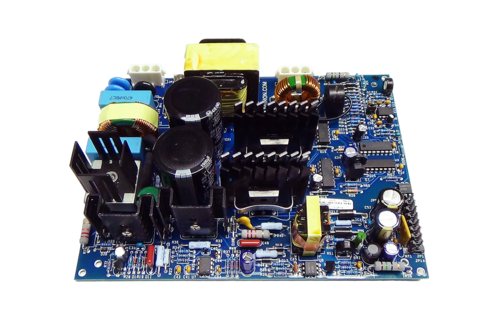

In the medical device coating process, having reliable and precise UV light curing is crucial. That’s where Uvitron’s UV arc lamp power supplies come in, empowering this critical stage of the process. These power supplies utilize cutting-edge high-frequency, solid-state, switch-mode technology, resulting in incredibly compact and lightweight units with tight output power regulation.

What’s more, Uvitron’s power supplies offer constant UV lamp power, ensuring repeatable cure times and long lamp life, even when faced with fluctuations in AC input or lamp voltages. This level of consistency and reliability is essential in achieving the desired results and ensuring product quality. With Uvitron’s power supplies, medical device manufacturers can have peace of mind knowing their UV light curing process is in good hands.

Discover the power and convenience of our full-featured arc lamp power supply, designed to deliver a constant power source for 400W, 600W, and 800W UV halide or other ultraviolet-emitting lamps. This innovative power supply is perfect for businesses operating in multiple countries, thanks to its auto-ranging AC input that eliminates the need for voltage selectors or rewiring when used internationally.

The lamp power regulation feature ensures consistent curing times by automatically adjusting the current reference to compensate for variations in lamp and line voltage. This means you’ll achieve reliable results even as the lamp ages, when it’s replaced, or when the input voltage fluctuates.

Additionally, our arc lamp power supply boasts a standby power mode that reduces UV arc lamp power to 1/2 for 400W and 1/3 for 600W, decreasing excess heat and power consumption during idle periods. This not only increases system reliability and efficiency but also reduces ambient temperature rise, making it an ideal choice for businesses looking to optimize their UV-curing processes.

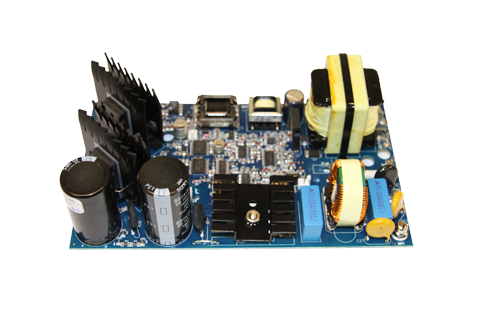

Economical Arc Lamp Power Supply

Upgrade your UV-curing system with our economical arc lamp power supply, a compact switch-mode power source designed to deliver constant power to 400W and 600W mercury vapor bulbs or medium pressure metal halide arc lamps. This versatile power supply is available in both 100/120AC and 200/240AC versions to accommodate international use, making it an ideal choice for businesses operating in multiple countries.

Our economical arc lamp power supply features a standby switch signal, reducing lamp output power to 1/2 for 400W and 1/3 for 600W during idle periods. This helps to minimize excess heat and power consumption, improving system reliability and efficiency while reducing ambient temperature rise. Additionally, the power supply includes an un-isolated 12V output for powering a local cooling fan and an integrated lamp igniter, eliminating the need for an external high-voltage starter.

With two input voltage range options, an integrated high-voltage lamp starter, and lamp power regulation for consistent curing times, our economical arc lamp power supply ensures reliable performance even as the lamp ages or when the input voltage fluctuates. The power supply also features a ready LED indicator, providing a visual cue when the lamp warm-up is complete.

HiWatt 2: Programmable Electronic Arc Lamp Ballast

Upgrade your UV-curing system with our HiWatt 2 programmable electronic arc lamp ballast, a dual-processor controlled, solid-state switching power supply designed for ultimate adaptability and performance. This innovative ballast is factory or customer software configurable via a PC serial port, allowing it to power a wide range of lamp types and utility power sources, making it a truly universal solution for various lamps and power sources worldwide.

The HiWatt 2 ballast is capable of powering arc lamps in the range of 1kW–20kW, with lamp voltages of 200–850V, from single or three-phase AC sources. It can even power two arc lamps in a series, as long as the total composite voltage does not exceed 850V. This versatility sets the HiWatt 2 apart as a single-unit solution for many types of lamps and applications.

Communication with customer-connected controllers or PCs is seamless via optically isolated digital logic signals, RS485 serial port, or USB port. This connectivity enables monitoring and control of lamp enable/disable, lamp dimming, and lamp cooling blower control. The HiWatt 2 can also optionally control motorized or pneumatic lamp shutters for added functionality.

In the intricate process of UV coating medical devices, reliable and efficient power supplies are indispensable. Uvitron’s power supplies play a critical role in facilitating the UV coating process, offering consistent energy delivery, optimized efficiency, regulatory compliance, and adaptability to emerging technologies. By providing solutions that streamline and enhance the medical device coating process, Uvitron is proud to contribute to the development of advanced, high-quality medical equipment that improves patient care and outcomes.